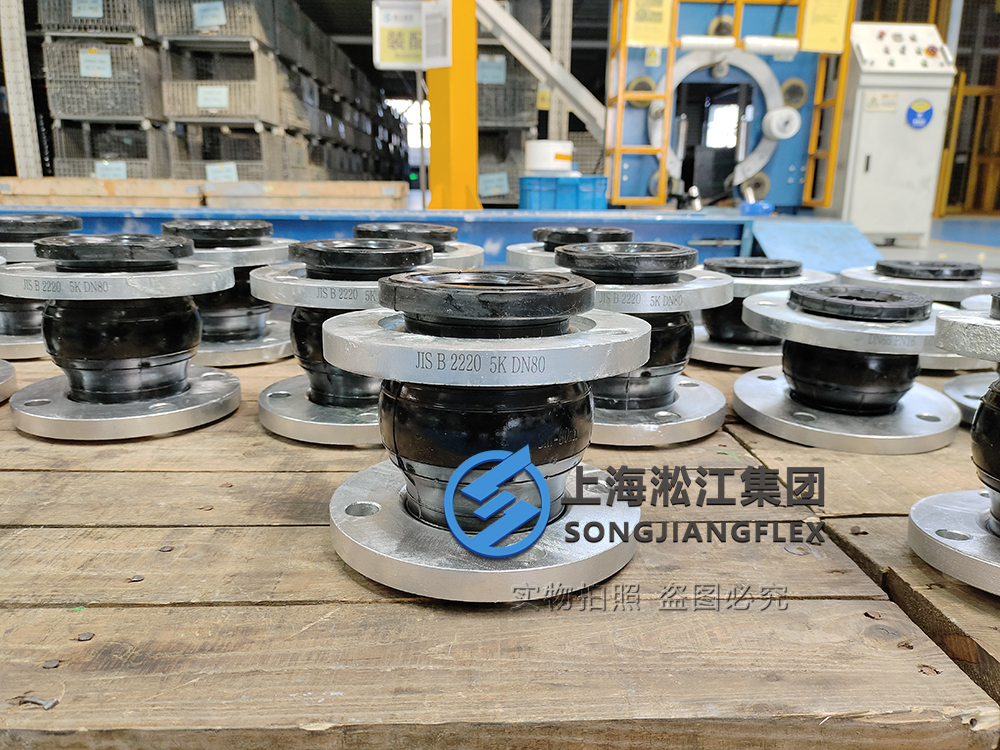

A JIS B 2220 5K DN80 rubber expansion joint is designed to reduce pipe stress and absorb vibrations. Learn how it complies with JIS valve standards and its critical role in industrial systems.

The JIS B 2220 5K DN80 rubber expansion joint provides flexible, durable performance, meeting JIS valve standards for piping systems. It’s crucial for systems requiring vibration absorption, thermal expansion compensation, and pressure resistance. This expansion joint is essential for achieving optimal performance in various applications, especially in the context of JIS flange and valve specifications.

Let’s explore the specifications, features, and applications of this important expansion joint according to JIS standards.

What is the JIS B 2220 Standard?

The JIS B 2220 standard defines the technical specifications for flanges, expansion joints, and valves used in industrial piping systems in Japan.

This standard ensures compatibility between components like JIS valves, flanges, and expansion joints, guaranteeing performance under pressure and vibration conditions. It covers the key dimensions and materials for components used in critical systems.

Understanding JIS valve standards and JIS flange dimensions (such as JIS 5K and JIS 20K flange dimensions) is essential for engineers and installers to ensure proper fitting and performance of piping systems. You can also refer to JIS valve PDF documentation for further details, which provide comprehensive information about various JIS standard components used in industrial piping systems.

What is a DN80 Rubber Expansion Joint?

DN80 refers to the nominal diameter of the rubber expansion joint, suitable for 80mm pipes. It plays a significant role in managing movement and vibration in industrial piping systems.

The DN80 rubber expansion joint fits perfectly within pipes of 80mm diameter, providing compensation for thermal expansion, vibrations, and pipe movement. It’s widely used in systems where pipe flexibility is needed.

Rubber expansion joints, such as the DN80 model, are used in many systems, from HVAC to high-pressure piping. Their flexible nature helps to avoid stress accumulation in pipes. For reference, you can check out the JIS F7400 PDF for more information on rubber expansion joint specifications, which details the construction and material characteristics suited for industrial applications.

What is the Purpose of a Rubber Expansion Joint?

Rubber expansion joints are vital for absorbing vibrations, compensating for thermal expansion, and reducing stress in piping systems.

These joints provide essential flexibility to absorb vibrations and prevent pipeline damage caused by movement, pressure, or temperature changes. Rubber expansion joints are often used in sensitive systems where movement compensation is crucial.

Rubber expansion joints serve to minimize mechanical stress in industrial systems. By accommodating pipe expansion and absorbing noise, they protect against long-term damage. These joints are also designed to reduce operational costs by preventing costly repairs due to pipe damage. For further technical insights, JIS standard PDF downloads can provide more in-depth guidance on installation and maintenance.

How Long Do Rubber Expansion Joints Last?

Rubber expansion joints typically last between 5 to 10 years, depending on environmental conditions and system use.

Regular maintenance and timely inspections are essential for extending the lifespan of rubber expansion joints. Proper care ensures they remain effective in reducing vibrations and managing pipe movements, ensuring long-term system reliability.

Factors such as pressure, temperature, and the chemicals flowing through the pipes can affect the lifespan of rubber expansion joints. The environment in which the system operates, including exposure to UV rays or aggressive chemicals, can also impact durability. Always refer to JIS standards and follow guidelines for the correct installation and maintenance process to extend the joint’s life.

What is the Size of a Standard Expansion Joint?

Standard expansion joints are available in a variety of sizes, ranging from small residential systems to large industrial applications.

Sizes like DN80 are common, but expansion joints can be tailored to fit different diameters, pressure ratings, and system needs. Choosing the correct size is critical for ensuring the expansion joint performs its function effectively.

The size selection for an expansion joint is based on factors like the nominal pipe diameter and the system’s movement requirements. Expansion joints are often custom-made to meet the specifications of the project. For example, check the JIS valve standards for guidelines on the right flange dimensions for your application, whether it’s a JIS 5K flange or a JIS 20K flange dimension.

What is the Difference Between Metal Expansion Joint and Rubber Expansion Joint?

Metal and rubber expansion joints differ in material flexibility, pressure resistance, and noise-dampening properties.

Metal expansion joints are designed for high-pressure environments, while rubber joints excel in absorbing vibrations and compensating for pipe movements. Understanding the differences is crucial for selecting the right joint for your system.

Metal expansion joints are ideal for systems with extreme temperature variations and high pressure. Rubber expansion joints, on the other hand, are preferred for their vibration and noise-damping properties, making them suitable for systems that require flexibility and stress relief. For further specifications, refer to JIS 1K flange dimensions for more details on material compatibility between rubber and metal joints.

How Do I Choose an Expansion Joint?

When selecting an expansion joint, it’s essential to consider factors like pipe diameter, pressure, temperature, and movement tolerance.

Choose an expansion joint that matches the pressure rating, temperature range, and system flexibility needs. Ensure it aligns with JIS flange standards and is compatible with your piping materials.

Different systems require different expansion joints. For instance, choosing between metal and rubber depends on the application. Review JIS valve standard PDFs for comprehensive selection criteria and dimension charts. These standards will help you make an informed decision for the best performance and durability.

What’s the Difference Between Metal and Rubber?

Metal and rubber components each have specific strengths, with metal offering high pressure resistance and rubber providing flexibility and vibration absorption.

Metal joints are ideal for harsh environments, while rubber expansion joints are better for reducing noise and vibration. Understanding their differences is key to proper selection.

Metal components, such as JIS butterfly valves, are used in high-pressure and temperature settings. Rubber joints are often used in industrial settings where flexibility and noise reduction are more important. Check the JIS valve standard PDF free download for further information on the properties of both materials and their respective applications.

Summary:

The JIS B 2220 5K DN80 rubber expansion joint is a vital component for efficient pipe management, offering flexibility, durability, and performance in compliance with JIS valve and flange standards.