The noise generated by resin cast dry type power transformers is typically low-frequency noise. Although the sound itself may not be loud, its impact is widespread, making it one of the common sources of noise in residential areas and office buildings. Prolonged exposure to transformer noise can cause significant mental stress. So, how can we effectively address the issue of excessive transformer noise? Here are some methods for noise reduction in resin cast dry type power transformers:

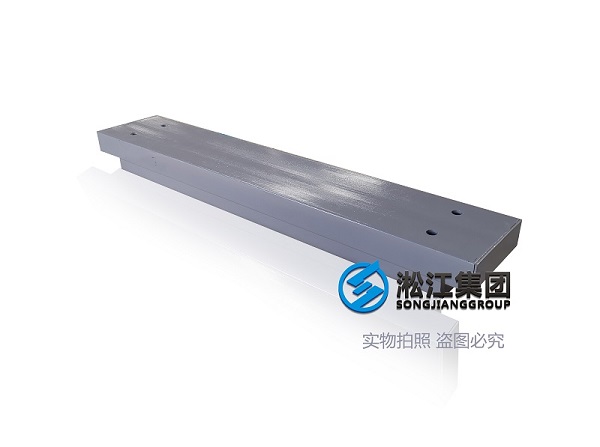

- Vibration Dampers: The primary noise issue with resin cast dry type power transformer equipment is vibration, which is the source of low-frequency noise. Therefore, the focus is on vibration reduction. For the main vibration, highly efficient elastic vibration dampers are installed on the base to effectively reduce the generation and propagation of vibrations. Additionally, soft connections are used for other transformer equipment to avoid resonance.

- Soundproofing for Transformer Rooms: Soundproofing and renovation for transformer rooms can involve increasing the thickness of brick walls, installing shock-absorbing layers on indoor floors, using soundproofing and vibration-reducing materials on walls, and using soundproof doors and windows. These measures combined can greatly enhance overall noise reduction. Moreover, ventilation outlets in transformer rooms should be equipped with silencers to ensure that all openings in the transformer room are soundproofed.

- After implementing vibration reduction and noise reduction methods at the equipment level, noise levels measured outside the equipment layer are consistently below 50 decibels, complying with relevant standards such as the “Urban Area Environmental Vibration Standard.”

Implementing vibration reduction and noise reduction measures at the equipment level involves addressing noise issues originating from the transformer itself, particularly those caused by vibration. Additionally, soundproofing and renovation of transformer rooms help minimize the impact of other noises on the external environment.