Rubber Joint Raw Material Introduction: Canvas Fabric

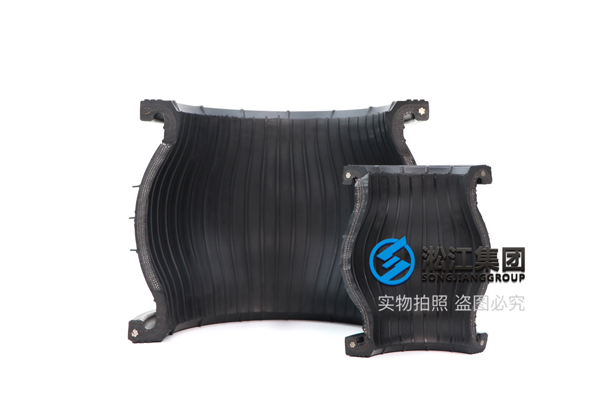

Shanghai Songjiang Vibration Absorber Co.,Ltd. is a manufacturer specializing in rubber joint products. Our company uses imported high-strength canvas fabric as the skeleton layer to produce rubber joints, ensuring a high-pressure effect with a 5-year warranty.

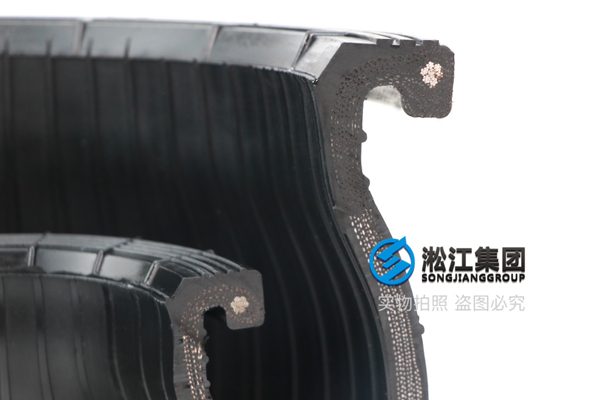

Canvas fabric products mainly serve as the framework, much like how reinforcing bars are essential in constructing buildings. One of the most common products utilizing canvas fabric as the framework layer is tires. We often see layers of canvas fabric inside car tires, serving to reinforce them.

Shanghai Songjiang Vibration Absorber Co.,Ltd. introduces what canvas fabric products are: Canvas fabric is a fabric used as the framework fabric for tires and other rubber products. It is woven with strong warp threads and medium to fine single weft threads. The warp threads are arranged closely, while the weft threads are arranged sparsely, resembling curtains, hence the name.

Canvas fabric is used as the framework for tires and other rubber products to withstand enormous pressure, impact loads, and intense vibrations. It is a crucial material that influences tire performance and lifespan. The warp threads (also known as canvas threads) bear the load, while the weft threads secure the position of the warp threads.

The requirements for canvas threads are:

- High strength and initial modulus

- Heat resistance

- Fatigue resistance

- Structural stability

- Ability to bond with rubber.

Canvas threads include cotton canvas threads, viscose rayon canvas threads, nylon canvas threads, steel wire canvas threads, nylon canvas threads, polypropylene canvas threads, aramid canvas threads, carbon fiber canvas threads, PEN canvas threads, etc.

Cotton canvas threads have low strength, requiring multiple layers of canvas fabric to manufacture tire bodies. However, due to the high frictional heat generated during use, its heat dissipation is slow, leading to a gradual reduction in application. High-strength viscose rayon canvas threads have advantages such as fatigue resistance, heat resistance, and minimal tire deformation. However, since viscose rayon threads are prone to moisture absorption, tires must be protected during use to prevent cracks and reduce strength.

Nylon canvas threads have high strength, providing good impact resistance and fatigue resistance to tire bodies, with minimal temperature rise. However, they exhibit thermal shrinkage and are prone to tire deformation. Steel wire canvas threads produce tire bodies with high strength, minimal rolling resistance, good impact resistance, and excellent abrasion resistance. However, they have high rigidity and may damage vehicle chassis components. Other types include polyester canvas threads, glass fiber canvas threads, etc.

In the 1970s, aromatic polyamide fiber canvas threads (see aromatic polyamide fibers) appeared, with advantages such as high strength, high modulus, high temperature resistance, and dimensional stability, suitable for tires with high performance requirements such as engineering vehicles and aircraft. In addition, carbon fiber canvas and PEN fiber are also future development trends.

The above information is provided by the Shanghai Rubber Joint Network.

For more information on “Rubber Joint Raw Material Introduction: Canvas Fabric,” please visit the official website of Shanghai Songjiang Vibration Absorber Co.,Ltd.