Struggling to find a hose that can handle high pressure and resist corrosion? Stainless steel braided hoses offer a durable solution for industrial applications, ensuring longevity and performance.

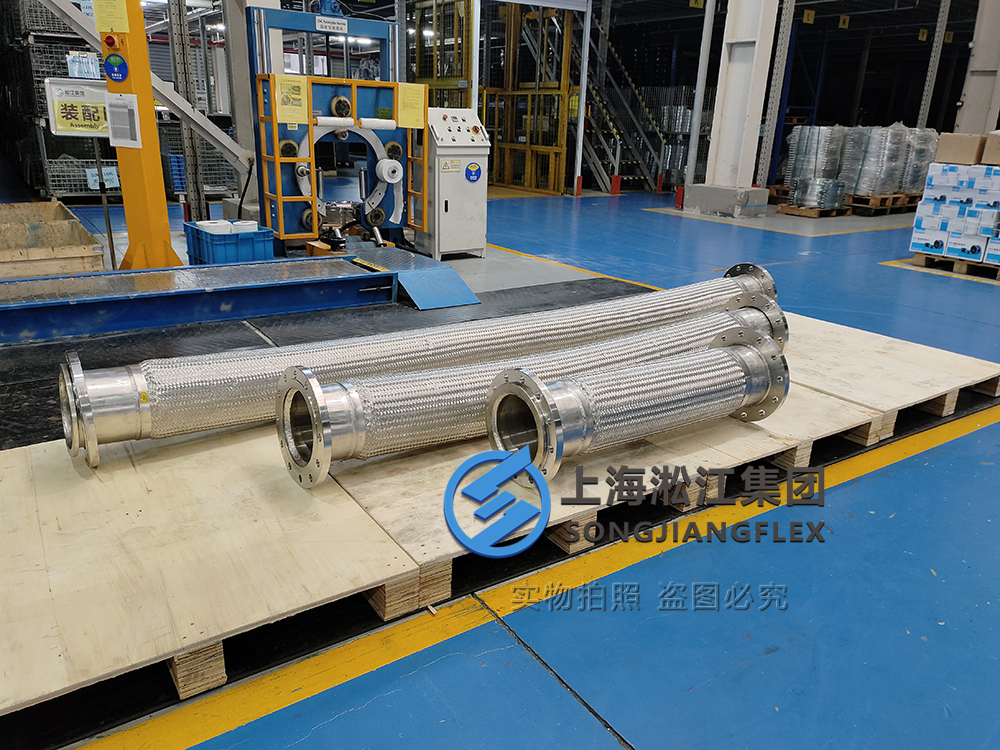

A stainless steel braided hose is a flexible hose reinforced with a braided layer of stainless steel, designed to withstand high pressure and resist corrosion. It is commonly used in high-temperature and high-pressure environments, providing essential support for industrial equipment and machinery.

Let’s explore more about stainless steel braided hoses and their advantages.

What does braided hose mean?

The term “braided hose” refers to a hose that has a protective layer of stainless steel braid around it, designed to enhance the hose’s durability and pressure resistance.

Braided hose means the hose is covered with a woven layer of stainless steel strands. This braiding gives the hose greater strength, flexibility, and durability, making it suitable for demanding environments such as hydraulic systems and high-pressure applications.

The braided layer serves as reinforcement, preventing the hose from expanding or bursting under high pressure. This design is especially useful in settings requiring high-pressure stainless steel braided hoses, where durability is a must. Additionally, this braid helps protect the inner tube from damage or wear, making it an excellent choice for long-term use.

Are braided stainless steel hoses better than rubber?

When it comes to durability and pressure tolerance, braided stainless steel hoses are often superior to rubber hoses, especially in high-demand environments.

Braided stainless steel hoses are typically more durable and heat-resistant compared to rubber hoses. They can handle higher pressures and temperatures, making them ideal for industrial applications such as in hydraulic systems, where pressure is a key concern.

In comparison, rubber hoses may be more flexible but are prone to wear and damage over time. A steel braided hose kit can provide a stronger, longer-lasting solution, especially in high-temperature and high-pressure situations. The stainless steel layer also provides corrosion resistance, ensuring the hose remains intact even in challenging environments.

What are the advantages of stainless steel braided hoses?

Stainless steel braided hoses offer many advantages, from durability to corrosion resistance, making them the go-to option for various industries.

The advantages of stainless steel braided hoses include high resistance to temperature extremes, corrosion, and abrasion, as well as excellent flexibility and strength. These properties make them ideal for use in high-pressure environments like hydraulic systems and industrial machinery.

The stainless steel braid acts as a protective layer, preventing damage from external forces and ensuring the hose maintains its integrity under pressure. Additionally, stainless steel braided flex hoses are resistant to wear, making them suitable for long-term applications in challenging environments. Their versatility and reliability make them an excellent choice for both industrial and commercial uses.

What is the difference between braided and corrugated stainless steel?

Both braided and corrugated stainless steel hoses have specific uses, but their structure and flexibility are what set them apart.

The primary difference between braided and corrugated stainless steel hoses is in their design and application. Braided hoses are flexible and reinforced, while corrugated hoses offer more rigidity and are typically used in high-vibration environments.

Braided hoses, like stainless steel braided hoses, provide more flexibility and are ideal for applications where movement is required. On the other hand, corrugated hoses are better suited for situations where durability and rigidity are necessary. Depending on your requirements, either option can serve as a reliable solution for your industrial needs.

How to maintain a stainless steel braided hose?

Regular maintenance is key to ensuring the longevity of your stainless steel braided hoses, especially in high-pressure environments.

To maintain a stainless steel braided hose, inspect it regularly for signs of wear or damage, especially in high-pressure areas. Clean the exterior to prevent corrosion, and ensure that all fittings are tight to avoid leaks.

Maintaining high-pressure stainless steel braided hoses involves regularly checking for leaks, abrasions, or signs of wear. Keeping the hose clean and free from debris helps prevent damage to the stainless steel braid. Additionally, ensuring that the stainless steel braided hose fittings are properly secured will help extend the hose’s lifespan.

How to choose the right stainless steel braided hose?

Choosing the right stainless steel braided hose depends on various factors, including pressure requirements, temperature, and the specific application.

When selecting a stainless steel braided hose, consider factors like pressure rating, temperature range, and the environment it will be used in. High-pressure applications require hoses with higher durability and resistance, such as high-pressure stainless steel braided hoses.

It’s important to match the hose’s specifications with your equipment’s needs. For example, if you’re working with hydraulic systems, you may need a steel braided hose kit that includes compatible fittings. Make sure the hose you choose is compatible with the fluid it will carry and can handle the required pressure.

What is the lifespan of a stainless steel braided hose?

The lifespan of a stainless steel braided hose varies depending on the operating conditions, including pressure, temperature, and maintenance.

A stainless steel braided hose can last anywhere from several years to a decade, depending on the conditions it is used in. Regular maintenance and proper use can extend the lifespan significantly.

To maximize the lifespan of your stainless steel braided hose, it is crucial to follow best practices in installation and maintenance. Inspecting the hose regularly for wear, and ensuring that it is used within its pressure and temperature limits, will help prolong its service life. Properly maintained hoses can last for many years without issues.

Summary

Stainless steel braided hoses offer durability, flexibility, and resistance to high pressure and corrosion. Whether you need a high-pressure stainless steel braided hose or a steel braided hose kit, these hoses are perfect for industrial applications requiring strength and longevity.