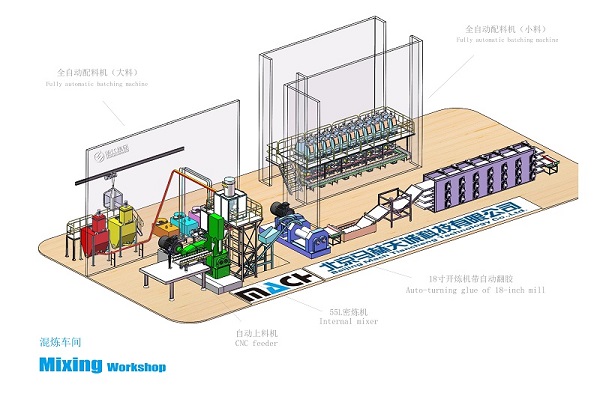

The official website of Shanghai Songjiang Vibration Absorber Co., Ltd. presents: 【Ingredients】Rubber Granule Automatic Batching System Put into Operation Information. In 2017, Songjiang Group invested 120 million yuan to establish a project with an annual output of 120 shock absorbers in Nantong, Jiangsu Province. Various automated production equipment was deployed in this project, and below is a detailed introduction to the rubber granule automatic batching system.

Fully Automatic Batching System: A fully automatic batching system is an automated system used in industrial production for precise material batching. It typically involves a computer with automatic batching algorithm software serving as the control system for the batching process. The system can simultaneously control multiple scales, various materials, and control output operations with intuitive, clear, and automatic recovery functions. It features powerful reporting capabilities, enabling extensive data recording, storage, and table printing. The system boasts high reliability and robust alarm notification functions, minimizing scrap rates to the lowest level. Equipped with online automatic monitoring software, it allows real-time monitoring of critical production information through a live online monitor.

Advantages:

- Automation: Achieves automation with computer-controlled conveying and feeding times.

- Computerized Feeding: Eliminates the need for manual intervention, ensuring accuracy and reliability.

- Computerized Weighing: Ensures flawless precision, facilitating smoother subsequent vulcanization processes.

- Dust Removal: Effectively resolves dust-related issues, enhancing the working environment.

Currently, there are no domestic rubber joint industries utilizing this fully automatic batching system. Therefore, for Songjiang Group, a powerhouse factory in rubber joint production, the absence of such a system would undermine its position in the industry. Songjiang Group recognizes the importance of staying at the forefront of technological advancement, and thus, has invested in additional new types of automated equipment at its Nantong factory. These investments will be gradually put into operation, ensuring the company’s competitiveness and standing in the industry.

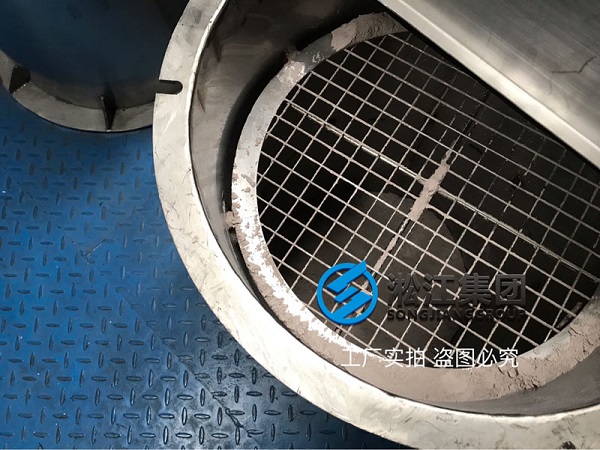

Rubber Granule Automatic Batching System Overview: The rubber granule automatic batching system is designed for the automatic batching of small materials in the rubber and plastic industries, with a measurement accuracy of up to 2%. It offers a high level of automation, which can save labor, improve product quality, enhance the working environment, and increase efficiency.

The rubber granule automatic batching system is not only suitable for the rubber and plastic industry but also adaptable to industries such as food, chemical, feed, and new energy, where small materials or measured ingredients are required. It primarily addresses the need for automatic proportionate batching of various raw materials in small quantities due to the diverse range of products and frequent changes in formulations. With a Nord automatic batching system, the cumbersome batching process can be automated, intelligent, and simplified.

Features of the Rubber Granule Automatic Batching System:

- Suitable for a wide variety of materials and multiple raw materials, ensuring high precision and fast batching speed.

- High level of automation, saving labor and enhancing efficiency.

- High-precision formulation provides optimal conditions for producing high-quality products.

- Fully automated control, eliminating the need for manual intervention.

- Avoids errors in manual weighing or formulation mistakes caused by human emotions, thereby significantly improving product yield.

- Conveyor batching system designed with industrial control, all operations conducted within enclosed pipelines, ensuring dust-free operation.

- Modular design simplifies maintenance and facilitates ease of use.

![[Shanxi Kangwei Hongtai Coal Washing Plant] Rubber Expansion Joint Contract](https://www.sungkiangflex.com/wp-content/themes/sj-1/timthumb.php?src=https://www.sungkiangflex.com/wp-content/uploads/2024/06/Shanxi-Kangwei-Hongtai-Coal-Washing-Plant-Rubber-Expansion-Joint-Contract-1.jpg&h=300&w=400&zc=1)